Quality is the foundation of LMTEK, and your satisfaction is our ultimate goal.

LMTEK is committed to providing you with high-quality display and control, embedded systems, and Industrial HMI products and solutions in a long-term and stable manner to meet the needs of your project or business development.

To this end, we strive for excellence in the design, manufacturing, and inspection processes to ensure optimal quality and timely delivery.

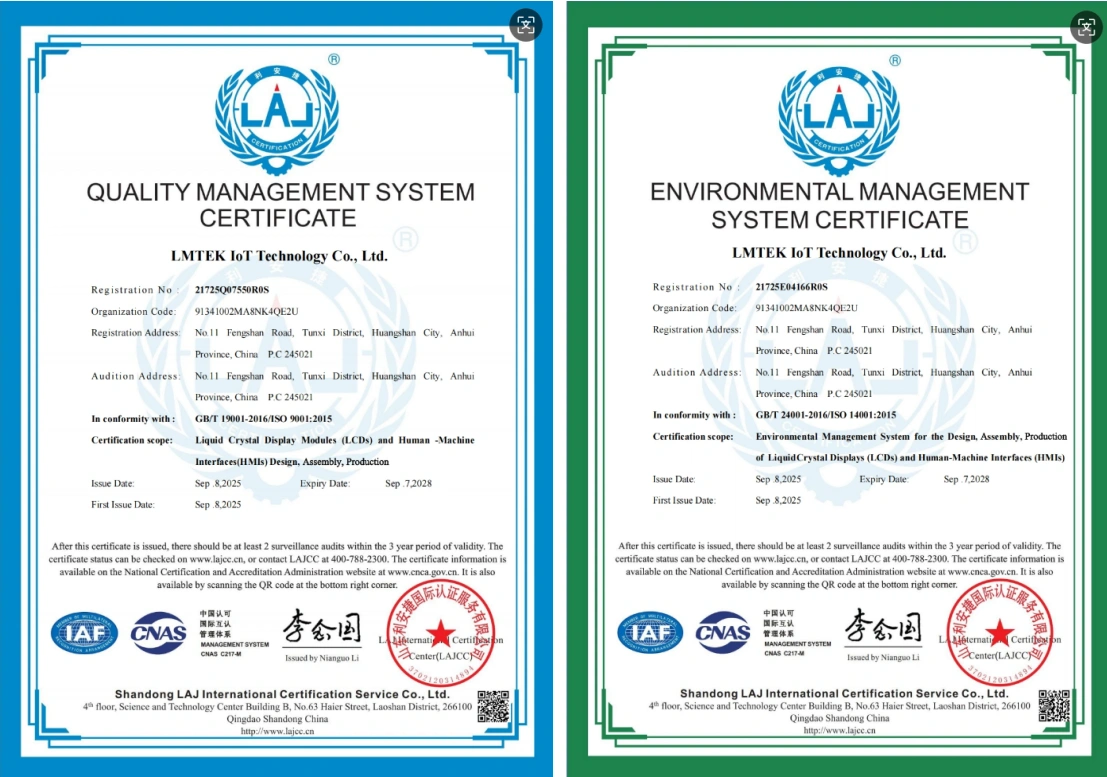

Compliant with International Certification

The production and manufacturing process of our products strictly complies with the requirements of ISO14001 environmental management system and ISO9001 quality management system certification.

In addition, our products meet the requirements of RoHS, REACH, and related industry standards such as CE, ensuring the safety and reliability of our products during use.

Supply Chain Process

Integrated quality management of the entire price supply chain process

Design Phase

Our experienced R&D team evaluates reliability and manufacturing feasibility during the design phase of your product.

Supplier Collaboration

We closely collaborate with selected suppliers and leverage the advantages of our group company and regional industrial clusters to ensure high-quality raw materials and components.

Production Control

Control measures are implemented at all production stages, including TFT LCD, touch screen manufacturing, SMT/PCBA assembly, injection molding sheet metal manufacturing, and final assembly.

Quality Control Process

Strict quality control process ISO 9001 and ISO 14001

LMTEK has established a comprehensive quality control process to monitor and manage product quality throughout the entire process through the following steps:

Incoming Quality Control

Inspect raw materials and components to ensure they are qualified.

In Process Quality Control

Real-time monitoring of critical production processes during the production process.

Outsourcing Audit

Select suppliers and conduct periodic audits to ensure their production processes meet requirements.

Final Quality Control

Comprehensive final inspection of finished products to ensure functionality and performance standards.

Outgoing Quality Control

Sampling inspection on products ready for shipment to ensure packaging and protection standards.